Plasma cutting is a method of shaping steel or other metals using a plasma torch to cut away unwanted parts, which has long been considered as a low-cost alternative to laser profiling. CNC plasma cutting allows for uniform metals beca...

Share

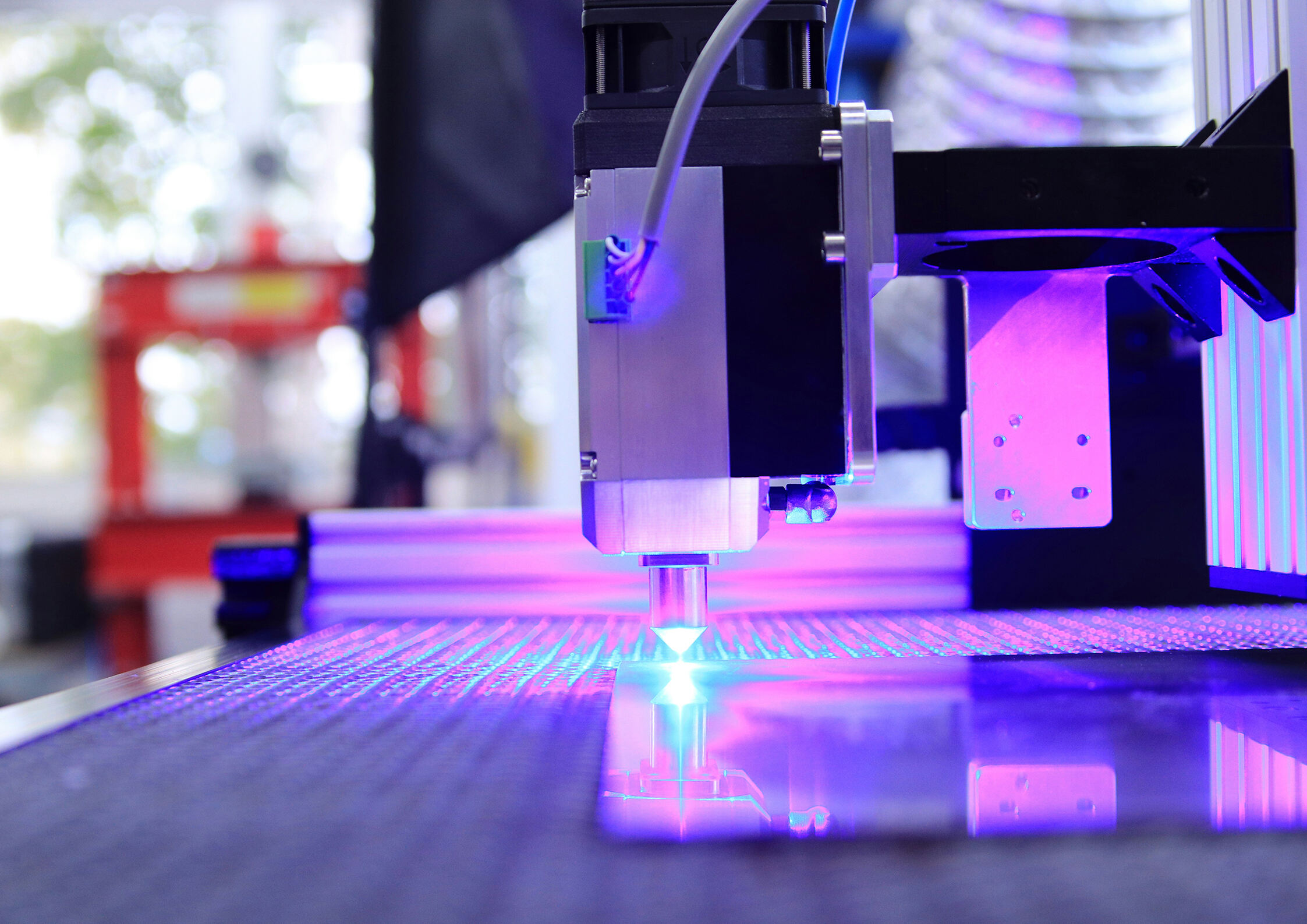

Plasma cutting is a method of shaping steel or other metals using a plasma torch to cut away unwanted parts, which has long been considered as a low-cost alternative to laser profiling. CNC plasma cutting allows for uniform metals because each piece can be cut in the same way as the one before. The operator can switch between multiple patterns to cut different shapes.

Plasma cutting is suitable for various metals, particularly mild steels and stainless steels producing an excellent edge finish. Materials ranging from 1mm through to 75mm mild steel can be cut with the plasma process and at relatively high speeds. The plasma cutting process can cut materials much faster than laser cut, which is for many the fastest and most productive way to cut parts for metal fabrication applications.